CVTE

Engineering & Robotics

Jeff Wildrick, Academy A Administrator – Ext. 291

Course & Program of Studies

Statement of Purpose

The Engineering & Robotics Program is a certified Project Lead the Way (PLTW) pre-engineering program. PLTW is a national program that forms partnerships among Public Schools, Higher Education Institutions, and the Private Sector to increase the quantity and quality of engineers and engineering technologists.

The program introduces students to the scope, rigor, and discipline of engineering, enabling them to develop logical thought processes and a broad technical knowledge base. Students participating in PLTW programs are better prepared for college engineering programs and more likely to be successful in those programs.

The exploration of various technology systems and manufacturing processes helps students learn how engineers and technicians use math, science, and technology in an engineering problem-solving process to benefit people. Students:

- Design and test digital electronic circuitry

- Learn problem-solving skills using a design and development process

- Model and analyze product solutions using solid modeling computer design software

- Apply the principles of robotics, automation, and CNC equipment to produce actual models of their three-dimensional designs

In their senior year, students apply these skills to solve a real engineering problem. Working in teams, students research, design, and construct a solution to an open-ended engineering problem.

PLTW certification provides students an opportunity to earn college credits for work completed in this program at the following colleges and universities:

- University of Colorado at Colorado Springs

- DeVry University

- Duke University

- New Hampshire Technical Institute

- Purdue University

- Rochester Institute of Technology

- University of Maryland-Baltimore County

- University of New Haven

- University of South Carolina

- Weber State University

The Engineering & Robotics program prepares students for success in pursuing careers in the areas of civil, architectural, electrical, and mechanical engineering.

Exploratory Program

The 9th-grade Engineering Technology Exploration program provides a comprehensive introduction to the world of engineering. This program is designed to spark students’ interest and help them make informed decisions about their future career paths.

Key Areas of Exploration:

- Safety: Understanding and practicing safety procedures in the engineering lab.

- Tool and Equipment Usage: Learning to use basic hand tools, power tools, and measuring instruments.

- Engineering Design Process: Following the engineering design process, from problem identification to solution implementation.

- Materials Science: Exploring the properties of different materials and their applications in engineering.

- Manufacturing Processes: Understanding manufacturing processes, such as machining, casting, and 3D printing.

- Career Exploration: Researching various engineering careers and their educational requirements.

Hands-On Projects:

- Simple Machine Projects: Designing and building simple machines, such as levers, pulleys, and gears.

- 3D Printing: Creating 3D models and printing physical objects.

- Robotics: Building and programming simple robots.

- Electronics: Exploring basic electronic circuits and components.

Assessments:

- In-Shop Competition: Participating in challenges that assess problem-solving, creativity, and technical skills.

- Written Assessments: Completing quizzes and tests to evaluate understanding of engineering concepts.

- Portfolio Development: Documenting projects and learning experiences in a portfolio.

By the end of the exploratory program, students will have a solid foundation in engineering principles and a better understanding of the diverse career opportunities available in the field. They will be well-prepared to make informed decisions about their future educational and career paths.

Freshman Program

This comprehensive first-year engineering program provides a strong foundation in fundamental engineering principles and skills. By focusing on project-based learning, students develop critical thinking, problem-solving, and teamwork abilities.

Key Areas of Focus

- Engineering Design Process:

- Problem identification and definition

- Research and brainstorming

- Concept generation and selection

- Design and development

- Testing and evaluation

- Iteration and refinement

- Technical Drawing and Modeling:

- Hand sketching and technical drawing

- 3D modeling using CAD software (e.g., TinkerCAD, SolidWorks, AutoCAD)

- Dimensioning and tolerancing

- Visualization and communication of design ideas

- Computational Methods:

- Basic statistical analysis

- Mathematical modeling and simulation

- Numerical methods

- Data analysis and interpretation

- Materials Science and Engineering:

- Properties of materials (mechanical, thermal, electrical)

- Material selection for specific applications

- Manufacturing processes (machining, casting, forging, etc.)

- Ethics and Professionalism:

- Ethical considerations in engineering practice

- Professional codes of conduct

- Intellectual property rights

- Sustainable design and environmental impact

- Communication Skills:

- Technical writing and report writing

- Oral presentations

- Teamwork and collaboration

Project-Based Learning:

- Design Challenges: Students work on open-ended design challenges, applying engineering principles to develop innovative solutions.

- Reverse Engineering: Disassembling and analyzing existing products to understand their design and manufacturing processes.

- Portfolio Development: Creating a professional portfolio showcasing projects and skills.

- Team Projects: Collaborating with peers to solve complex engineering problems.

By the end of the first year, students will have a solid foundation in engineering principles, problem-solving skills, and technical abilities. They will be well-prepared to advance to more specialized engineering courses in subsequent years.

Sophomore Program

3D MODELING/PRINT AND DESIGN (3DMPD)

This course provides a comprehensive introduction to parametric solid modeling using SolidWorks, a powerful industry-standard software. Students will learn how to effectively create, modify, and analyze 3D models, preparing them for careers in engineering, design, and manufacturing.

Key Topics:

- SolidWorks Interface: Understanding the user interface and navigation tools.

- Sketching: Creating precise 2D sketches as the foundation for 3D models.

- Features: Utilizing features like extrude, revolve, sweep, and loft to create complex 3D models.

- Assembly Modeling: Creating assemblies by combining multiple parts and defining relationships between them.

- Drawing Creation: Generating detailed 2D engineering drawings from 3D models.

- 3D Printing: Understanding 3D printing technology and preparing models for printing.

- Design for Manufacturing and Assembly (DFMA): Considering manufacturability and assembly considerations during the design process.

- Tolerance Analysis: Analyzing tolerances to ensure part accuracy and functionality.

Through hands-on projects and exercises, students will develop the following skills:

- Problem-solving: Identifying and solving design challenges.

- Critical Thinking: Analyzing design requirements and making informed decisions.

- Spatial Reasoning: Visualizing and understanding 3D objects.

- Technical Communication: Effectively communicating design ideas through drawings and models.

By the end of this course, students will be proficient in using SolidWorks to create complex 3D models, generate accurate engineering drawings, and prepare models for 3D printing. They will be well-prepared for further studies in engineering, design, or manufacturing.

DIGITAL ELECTRONICS (DE)

This course provides a comprehensive introduction to the fundamentals of electronics, with a focus on digital electronics.

Key Topics:

Analog Electronics:

- Basic Electrical Concepts: Voltage, current, resistance, and Ohm’s Law.

- Electronic Components: Resistors, capacitors, inductors, diodes, and transistors.

- Circuit Analysis: Analyzing simple circuits using circuit analysis techniques.

- Power Supplies: Understanding different types of power supplies and their applications.

Digital Electronics:

- Binary Number System: Converting between binary, decimal, and hexadecimal number systems.

- Logic Gates: Understanding the operation of AND, OR, NOT, NAND, NOR, XOR, and XNOR gates.

- Boolean Algebra: Simplifying Boolean expressions using Boolean algebra.

- Combinational Logic Circuits: Designing and analyzing combinational circuits, such as adders, subtractors, encoders, and decoders.

- Sequential Logic Circuits: Understanding flip-flops, counters, and registers.

- Microcontrollers: Introduction to microcontrollers and their applications.

- Digital Signal Processing (DSP): Basic concepts of DSP, including sampling, quantization, and filtering.

Hands-on Experience:

- Circuit Design and Simulation: Using software tools to design and simulate circuits.

- Breadboarding and Prototyping: Building and testing electronic circuits on breadboards.

- Soldering: Soldering electronic components to create circuits.

- Troubleshooting: Identifying and fixing faults in electronic circuits.

By the end of this course, students will be able to:

- Analyze and design basic electronic circuits.

- Understand the principles of digital electronics.

- Use electronic test equipment to measure and troubleshoot circuits.

- Apply problem-solving skills to design and implement electronic systems.

- Prepare for advanced courses in electronics, computer engineering, or related fields.

This course provides a strong foundation in electronics, preparing students for a variety of careers in engineering, technology, and related fields.

Sophomore Related 1

Introduction to Engineering Mathematics

This course provides a solid foundation in mathematics, specifically tailored to the needs of engineering students.

Key Topics:

Algebra

- Linear Equations: Solving linear equations and inequalities.

- Quadratic Equations: Solving quadratic equations by factoring, completing the square, and using the quadratic formula.

- Functions: Understanding functions, their graphs, and transformations.

- Polynomials: Operations with polynomials, factoring, and solving polynomial equations.

- Rational Expressions: Simplifying, adding, subtracting, multiplying, and dividing rational expressions.

- Radical Expressions: Simplifying and operating with radical expressions.

- Exponential and Logarithmic Functions: Understanding the properties and applications of exponential and logarithmic functions.

Trigonometry

- Trigonometric Functions: Defining and using sine, cosine, and tangent functions.

- Trigonometric Identities: Proving and applying trigonometric identities.

- Solving Triangles: Using trigonometric ratios to solve right triangles and oblique triangles.

- Trigonometric Graphs: Graphing trigonometric functions.

- Applications of Trigonometry: Solving real-world problems involving angles, distances, and forces.

Engineering Applications:

- Unit Conversions: Converting between different units of measurement (e.g., metric and imperial).

- Geometric Calculations: Using geometry to solve problems in engineering design.

- Trigonometric Applications: Applying trigonometry to solve problems in mechanics, statics, and dynamics.

- Data Analysis: Analyzing and interpreting data using statistical methods.

Problem-Solving and Critical Thinking:

- Problem-Solving Strategies: Developing problem-solving skills to tackle engineering challenges.

- Critical Thinking: Analyzing problems, identifying key information, and developing solutions.

By the end of this course, students will be well-prepared to apply mathematical concepts to engineering problems. They will be able to:

- Solve algebraic and trigonometric equations.

- Use mathematical models to analyze real-world situations.

- Apply mathematical principles to engineering design.

- Communicate mathematical ideas effectively.

Sophomore Related 2

CNC Programming

This course provides a comprehensive introduction to the principles and techniques of CNC milling. Students will learn how to program and operate CNC milling machines to produce precise and complex parts.

Key Topics:

- CNC Machine Basics:

- Components of a CNC milling machine

- CNC machine operation and safety procedures

- Coordinate systems (Cartesian, polar)

- G-Code Programming:

- G-code fundamentals: G00, G01, G02, G03

- M-code functions (spindle speed, coolant on/off, etc.)

- Tool path programming

- Cutting tool selection and tool path optimization

- Part programming techniques (manual and CAM)

- Simulated Machine Setup and Operation:

- Setting up the machine for various machining operations

- Loading and unloading parts

- Tool changes

- Zeroing and offsetting

- Monitoring and troubleshooting

By the end of this course, students will be able to:

- Understand the basic principles of CNC machining.

- Write G-code programs for CNC milling machines.

- Troubleshoot common CNC machine problems.

This course provides a strong foundation in CNC machining, enabling students to pursue careers in manufacturing, engineering, and related fields.

Junior Program

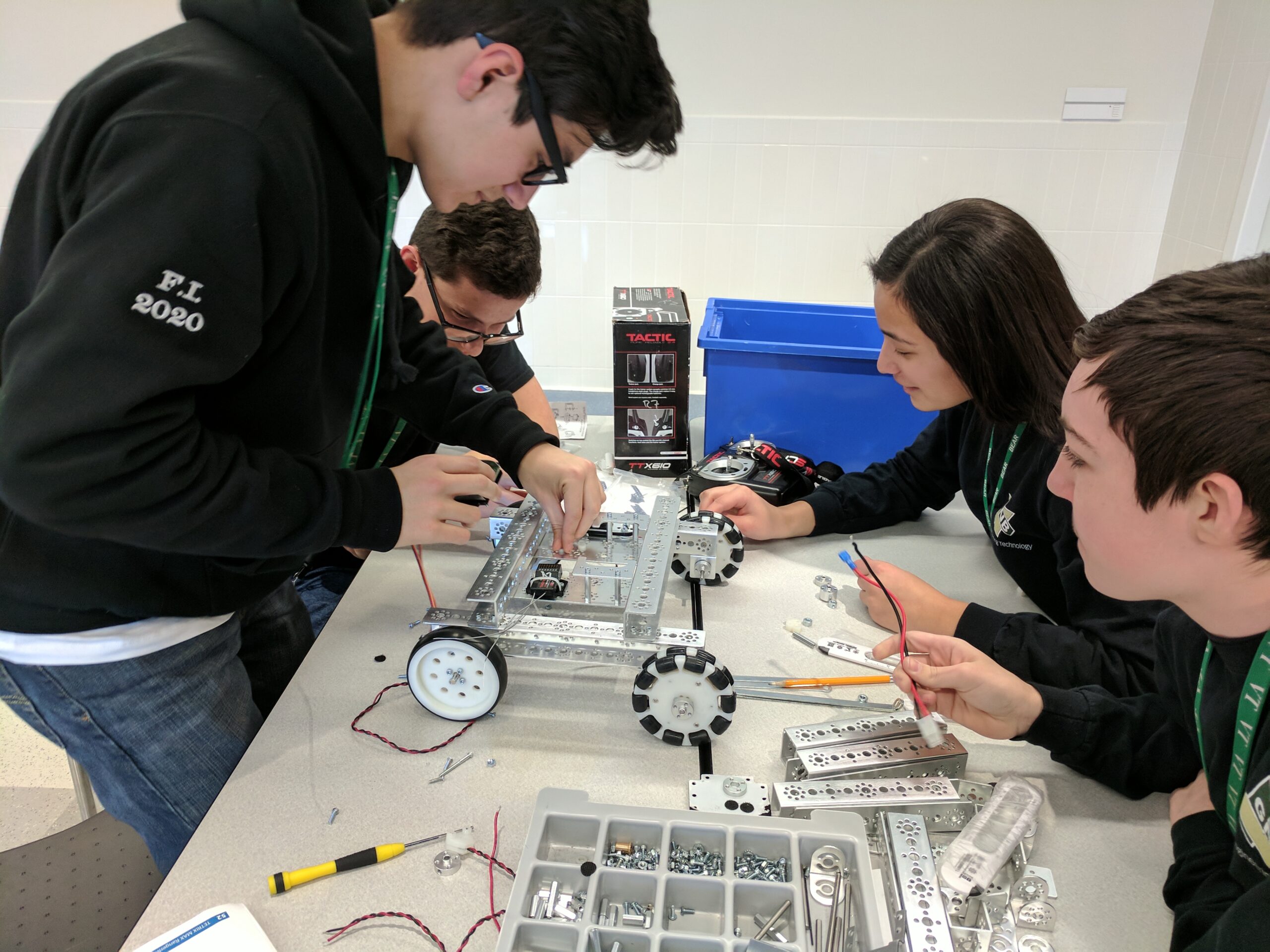

ROBOTICS & AUTOMATION TECHNOLOGY (RAT)

This course provides a comprehensive overview of robotics and automation, focusing on the principles, design, and implementation of automated systems.

Key Topics:

Introduction to Robotics:

- History and evolution of robotics

- Basic components of a robot (actuators, sensors, controllers)

- Degrees of freedom and workspace

- Robot kinematics and dynamics

Robot Programming and Control:

- Robot programming languages (e.g., RAPID, KRL)

- Joint-space and Cartesian space programming

- Path planning and trajectory generation

- Sensor integration (vision, force, tactile)

Automation Systems:

- Programmable Logic Controllers (PLCs)

- Human-Machine Interfaces (HMIs)

- Industrial automation systems

- Internet of Things (IoT) applications in automation

Robotics Applications:

- Industrial robotics (assembly, welding, painting)

- Mobile robotics (AGVs, autonomous vehicles)

- Service robotics (healthcare, hospitality)

Mechatronics:

- Integration of mechanical, electrical, and computer engineering principles

- Design and implementation of mechatronic systems

- Sensor fusion and data acquisition

Hands-on Projects:

- Designing and building robotic systems

- Programming robots to perform tasks

- Integrating sensors and actuators

- Troubleshooting and debugging robotic systems

- Remotely operating robotic vehicles

By the end of this course, students will be able to:

- Understand the fundamental principles of robotics and automation.

- Design, program, and operate robotic systems.

- Analyze and troubleshoot robotic systems.

- Apply robotics and automation concepts to real-world problems.

- Collaborate with others to develop innovative robotic solutions.

This course provides a solid foundation in robotics and automation, preparing students for careers in engineering, manufacturing, and other related fields.

COMPUTER INTEGRATED MANUFACTURING (CIM)

This course provides a comprehensive overview of computer-integrated manufacturing (CIM), focusing on the integration of computer technology and manufacturing processes.

Key Topics:

Computer-Aided Design (CAD):

- 3D modeling using CAD software (e.g., SolidWorks, AutoCAD)

- Creating detailed engineering drawings

- Designing for manufacturability and assembly

- Simulation and analysis of designs

Computer-Aided Manufacturing (CAM):

- Generating CNC programs using CAM software (e.g., Mastercam)

- Setting up and operating CNC machines

- Tool path generation and optimization

- Post-processing and machine code generation

Manufacturing Processes:

- Traditional Machining: Milling, turning, drilling, and grinding

- Additive Manufacturing: 3D printing and rapid prototyping

- CNC Machining: Programming and operating CNC machines

- Robotics and Automation: Understanding the role of robots in manufacturing

Quality Control and Inspection:

- Using precision measuring instruments (calipers, micrometers, etc.)

- Performing quality control checks

- Implementing statistical process control (SPC)

Project-Based Learning:

- Designing and manufacturing complex parts and assemblies

- Optimizing manufacturing processes

- Troubleshooting and problem-solving

- Collaborating with other team members

By the end of this course, students will be able to:

- Use CAD software to create complex 3D models.

- Generate CNC programs for various machining operations.

- Operate CNC machines safely and efficiently.

- Inspect and measure parts to ensure quality.

- Apply lean manufacturing principles to improve efficiency.

- Understand the impact of technology on manufacturing processes.

This course prepares students for careers in manufacturing engineering, mechanical engineering, and related fields. It provides a strong foundation in the principles and practices of computer-integrated manufacturing, enabling students to contribute to the development and production of innovative products.

Junior Related 1

Principles of Engineering I (Mechanics & Materials)

This course provides a solid foundation in the fundamentals of engineering. By exploring key concepts and applying them to real-world problems, students will develop a strong understanding of the engineering design process and the role of engineers in society.

Key Topics:

- Mechanisms:

- Types of mechanisms (linkages, cams, gears)

- Kinematic analysis of mechanisms

- Design and analysis of mechanical systems

- Statics:

- Forces and moments

- Equilibrium of rigid bodies

- Stress and strain analysis

- Structural analysis of beams and trusses

- Materials Science:

- Material properties (strength, stiffness, ductility, etc.)

- Material selection and processing

- Failure analysis and material testing

- Energy and Power:

- Energy sources and conversion (renewable and non-renewable)

- Power transmission and distribution

- Energy efficiency and sustainability

- Engineering Design Process:

- Problem identification and definition

- Research and information gathering

- Concept generation and selection

- Design and development

- Testing and evaluation

- Optimization and refinement

Skills and Competencies:

- Problem-solving and critical thinking: Identifying and solving complex engineering problems.

- Technical communication: Effectively communicating ideas through written and oral presentations.

- Teamwork and collaboration: Working effectively with others in a team environment.

- Experimentation and testing: Conducting experiments and interpreting results.

By the end of this course, students will be well-prepared for further studies in engineering and will have a strong foundation in the fundamental principles of engineering design and analysis.

Junior Related

Principles of Engineering II (Energy & Power)

This introductory engineering course provides a solid foundation in fundamental engineering principles and concepts. By exploring a variety of topics, students will gain a broad understanding of the engineering field and its impact on society.

Key Topics:

- Engineering Design Process:

- Problem identification and definition

- Research and information gathering

- Ideation and concept generation

- Design and development

- Testing and evaluation

- Optimization and refinement

- Mechanics:

- Statics and dynamics

- Forces, moments, and equilibrium

- Kinematics and kinetics

- Materials Science:

- Mechanical properties of materials (strength, stiffness, ductility)

- Material selection and processing

- Energy and Power:

- Energy sources and conversion

- Power systems and transmission

- Energy efficiency and sustainability

- Fluid Mechanics:

- Fluid properties and behavior

- Fluid flow and pressure

- Hydraulic and pneumatic systems

- Thermodynamics:

- Heat transfer and energy conversion

- Thermodynamics laws and applications

Hands-on Projects:

- Design Challenges: Working in teams to solve engineering problems.

- 3D Modeling and CAD: Using CAD software to design and model engineering components.

- Robotics and Automation: Building and programming robots.

- Material Testing: Conducting experiments to test the properties of materials.

By the end of this course, students will be able to:

- Apply engineering principles to solve real-world problems.

- Use engineering tools and software to design and analyze systems.

- Communicate technical information effectively.

- Work collaboratively with others to achieve common goals.

- Develop critical thinking and problem-solving skills.

This course provides a solid foundation for further studies in engineering and prepares students for a variety of careers in engineering, technology, and related fields.

Senior Program

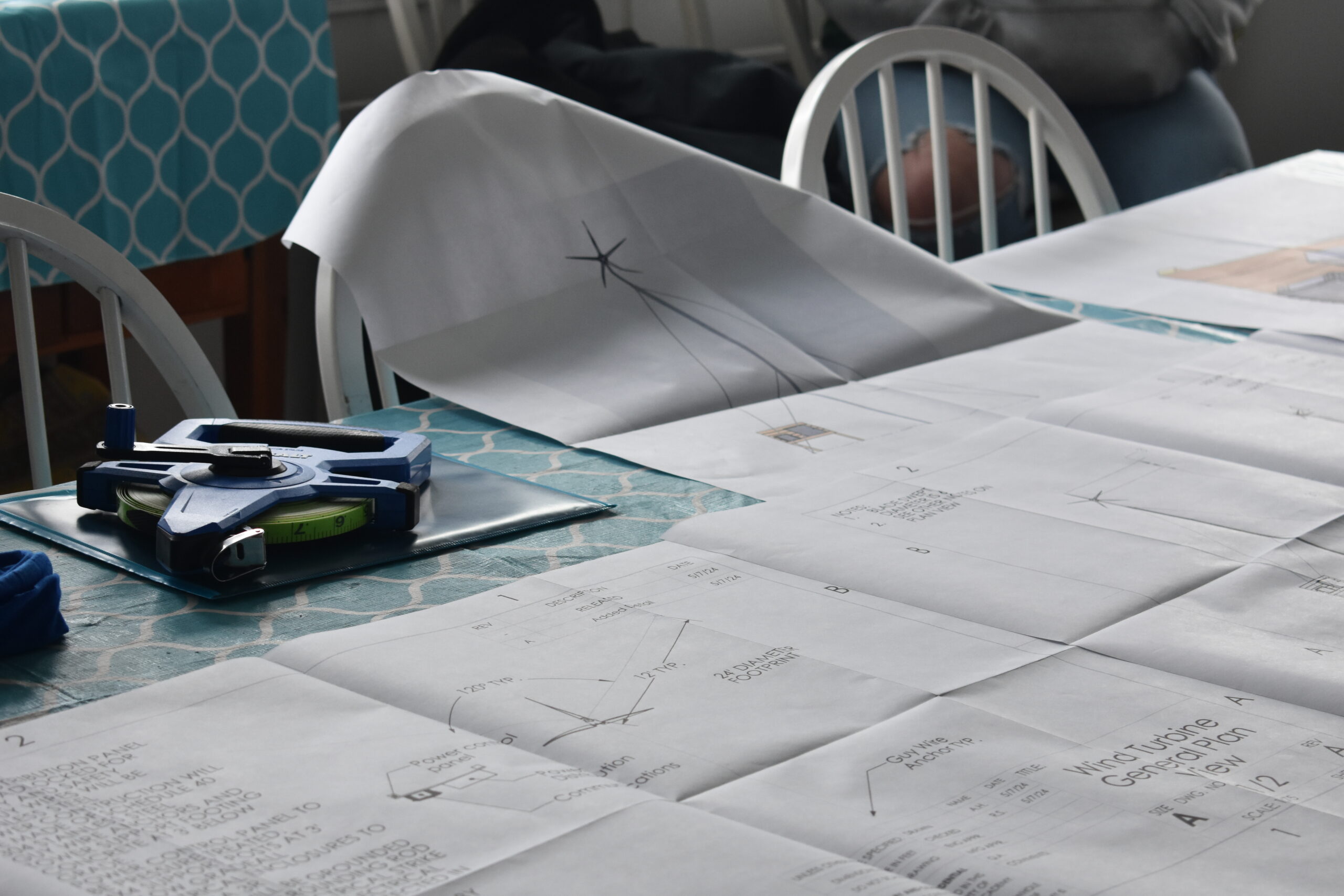

ENGINEERING DESIGN AND DEVELOPMENT (EDD)

This senior-level engineering course provides students with the opportunity to apply their knowledge and skills to a real-world engineering challenge. By following the engineering design process, students will develop innovative solutions and gain valuable experience in project management, teamwork, and technical communication.

Key Elements of the Course:

- Problem Identification and Research:

- Identifying a real-world problem that needs a solution.

- Conducting research to understand the problem and potential solutions.

- Analyzing existing solutions and identifying areas for improvement.

- Design and Prototyping:

- Brainstorming and concept generation.

- Creating detailed design drawings and models.

- Using CAD software (e.g., SolidWorks, AutoCAD) for 3D modeling and design.

- Utilizing manufacturing techniques like 3D printing, laser cutting, and CNC machining.

- Assembling and testing prototypes.

- Testing and Evaluation:

- Developing test plans to evaluate the performance of the prototype.

- Collecting and analyzing data.

- Identifying design flaws and areas for improvement.

- Iteration and Refinement:

- Modifying the design based on test results.

- Re-designing and re-testing as needed.

- Documentation and Presentation:

- Creating technical documentation (drawings, reports, presentations).

- Developing a professional portfolio.

- Presenting the project to a panel of judges or industry professionals.

Skills and Competencies:

- Problem-solving and critical thinking: Identifying problems and developing creative solutions.

- Teamwork and collaboration: Working effectively with others in a team environment.

- Technical communication: Communicating complex technical information clearly and concisely.

- Project management: Planning, organizing, and managing projects.

- Time management: Effectively managing time and resources.

- Ethical considerations: Understanding the ethical implications of engineering decisions.

By completing this capstone project, students will gain valuable experience in the engineering design process, develop strong problem-solving and critical thinking skills, and be well-prepared for further education or careers in engineering and related fields.

CIVIL ENGINEERING AND ARCHITECTURE LAB

This course provides a solid foundation in the principles and practices of civil engineering and architecture. By exploring the interdisciplinary nature of these fields, students will gain a comprehensive understanding of the design, construction, and maintenance of built environments.

Key Topics:

- Fundamental Concepts:

- Historical context of civil engineering and architecture

- The role of engineers and architects in society

- The design process from concept to construction

- Structural Engineering:

- Loads and stresses on structures

- Structural materials (steel, concrete, timber)

- Structural analysis techniques (static and dynamic analysis)

- Architectural Design:

- Design principles and elements (line, shape, color, texture, space)

- Building codes and regulations

- Sustainable design and green building practices

- Site Planning and Development:

- Site analysis and selection

- Zoning and land use regulations

- Grading and drainage design

- Landscape architecture and site planning

- Construction Methods and Materials:

- Construction materials (concrete, steel, timber, masonry)

- Construction techniques and equipment

- Quality control and inspection

- Computer-Aided Design (CAD):

- Using CAD software (e.g., AutoCAD, Revit, Chief Architect) for 2D and 3D modeling

- Creating construction drawings and blueprints

Hands-on Projects:

- Model Building: Constructing physical models of buildings and structures.

- Site Analysis and Planning: Analyzing a site and developing a site plan.

- Architectural Design: Designing buildings and spaces, considering factors such as function, aesthetics, and sustainability.

- Project Documentation: Creating detailed project documentation, including drawings, specifications, and reports.

By the end of this course, students will have a strong foundation in the principles of civil engineering and architecture. They will be able to apply these principles to real-world problems and develop innovative design solutions. Additionally, students will gain experience in using industry-standard software to create professional-quality drawings and models.

SENIOR ROBOTICS

This senior-level robotics course provides students with a comprehensive understanding of robotics and automation principles, and allows them to apply these concepts to real-world challenges.

Key Areas of Focus:

- Mechanical Design:

- Designing and building robotic mechanisms (e.g., arms, grippers, chassis)

- Selecting appropriate materials and manufacturing processes

- Utilizing CAD software (e.g., SolidWorks) for 3D modeling and design

- Electrical Systems:

- Circuit design and analysis

- Sensor integration (e.g., ultrasonic, infrared, vision)

- Actuator selection and control (motors, servos)

- Power distribution and battery management

- Programming and Control:

- Microcontroller programming (e.g., Arduino, Raspberry Pi)

- Robot programming languages (e.g., C++, Python)

- Control algorithms and feedback control

Projects and Challenges:

- VEX Robotics: Designing and building VEX robots to compete in challenges.

- Underwater ROV: Designing and building a remotely operated vehicle for underwater exploration.

Skills and Competencies:

- Problem-solving and critical thinking: Identifying and solving complex engineering problems.

- Teamwork and collaboration: Working effectively with others to achieve common goals.

- Technical communication: Presenting ideas clearly and concisely.

- Project management: Planning, executing, and evaluating projects.

- Ethical considerations: Understanding the ethical implications of robotics and automation.

By the end of this course, students will have a strong foundation in robotics and automation, and be well-prepared for further studies or careers in engineering, computer science, and related fields.

Senior Related 1

Civil Engineering & Architecture I (CEA)

This course provides a foundational understanding of civil engineering and architecture, highlighting the synergistic relationship between these two fields. Students will explore the fundamental principles of design, construction, and project management.

Key Topics:

- Introduction to Civil Engineering and Architecture:

- Historical development and contemporary challenges.

- The role of civil engineers and architects in society.

- Interdisciplinary nature of civil engineering and architecture.

- Design Process:

- Identifying client needs and project goals.

- Conceptual design and schematic design phases.

- Design development and construction document phases.

- Project management and construction administration.

- Structural Engineering:

- Loads and stresses on structures.

- Structural materials (steel, concrete, timber)

- Structural analysis techniques (static and dynamic analysis)

- Architectural Design:

- Principles of design (balance, rhythm, proportion, emphasis)

- Building codes and regulations

- Sustainable design and green building practices

- Site Planning and Development:

- Site analysis and selection

- Zoning and land use regulations

- Grading and drainage design

- Landscape architecture and site planning

- Construction Methods and Materials:

- Construction materials (concrete, steel, timber, masonry)

- Construction techniques and equipment

- Quality control and inspection

- Computer-Aided Design (CAD):

- Using CAD software (e.g., AutoCAD, Revit) for 2D and 3D modeling.

- Creating construction drawings and blueprints.

- Performing structural analysis and simulations.

Hands-on Projects:

- Model Building: Constructing physical models of buildings and structures.

- Site Analysis and Planning: Analyzing a site and developing a site plan.

- Structural Design: Designing simple structures using structural analysis software.

- Architectural Design: Designing buildings and spaces, considering factors such as function, aesthetics, and sustainability.

By the end of this course, students will have a solid understanding of the fundamental principles of civil engineering and architecture. They will be able to apply these principles to real-world problems and develop innovative design solutions. Additionally, students will gain experience in using industry-standard software to create professional-quality drawings and models.

Senior Related 2

Civil Engineering & Architecture II (LEED Green Prep) – Elective

This curriculum provides a comprehensive introduction to green building principles and practices, with a focus on LEED certification. By understanding and applying LEED standards, students can contribute to the creation of sustainable and environmentally responsible buildings.

Key Topics:

- Green Building Principles:

- Understanding the concept of sustainable development

- Identifying the environmental and social impacts of buildings

- Exploring the benefits of green building (energy efficiency, reduced environmental impact, improved occupant health and well-being)

- LEED Rating System:

- Overview of the LEED rating system and its various certification levels

- Understanding the LEED certification process and the role of LEED professionals

- Identifying the key areas of focus in LEED (sustainable sites, water efficiency, energy efficiency, materials and resources, indoor environmental quality, innovation, and regional priority credits)

- Sustainable Site Design:

- Site selection and development

- Minimizing site disturbance and protecting natural resources

- Implementing sustainable site design strategies (e.g., native landscaping, rainwater harvesting, permeable paving)

- Water Efficiency:

- Reducing water consumption through efficient fixtures and systems

- Implementing water conservation strategies (e.g., rainwater harvesting, water recycling)

- Energy Efficiency:

- Understanding building energy use and energy performance

- Implementing energy-efficient design strategies (e.g., high-performance building envelope, efficient HVAC systems, renewable energy)

- Materials and Resources:

- Selecting sustainable building materials and products

- Reducing waste and promoting recycling

- Promoting sustainable procurement practices

- Indoor Environmental Quality:

- Improving indoor air quality through ventilation and filtration

- Controlling indoor pollutants and contaminants

- Designing for occupant comfort and productivity

- Innovation and Regional Priority Credits:

- Exploring innovative strategies to achieve LEED certification

- Understanding regional priorities and local building codes

By the end of this course, students will be well-prepared to:

- Understand the principles of sustainable building design.

- Apply LEED rating system criteria to projects.

- Identify and implement strategies to reduce environmental impact.

- Contribute to the development of sustainable and resilient communities.

This curriculum empowers students to become leaders in the green building movement, driving positive change and creating a more sustainable future.

Certifications

- OSHA 10

- Certified Solidworks Associate

Career Opportunities

- Product Designer

- CNC Programmer

- CAD technician

- Engineering Technician

- Mechatronics Technician

- Automation and Robotics

- Electrical engineer

- Computer engineer

- Mechanical engineer

- Industrial engineer

- Civil or Architectural engineer

- Project Manager

- Certified Production Technician CPT)

- Quality Inspectors

- Technical Sales Manager

- Audio/Video Specialist

- Mobile Electronics Installer

- Research Laboratory

- Technician

- Operations Engineer

Post-Secondary Education

- Mechanical Engineer

- Bio-Tech Engineer

- Environmental Engineer

- Electrical Engineer

- Aerospace Engineer

- Engineering Robotic and Automation

- Architectural Engineer

- Civil Engineer

- Electromechanical Engineer