CVTE

Machine Technology

Guy Shepherd, Academy C Administrator – Ext. 113

Course & Program of Studies

Statement of Purpose

The Machine Technology program at GNBRVTHS provides a solid foundation in the fundamentals of manufacturing. Key areas of focus include:

Fundamental Machine Shop Skills:

- Safety: Understanding and practicing safety procedures in the machine shop.

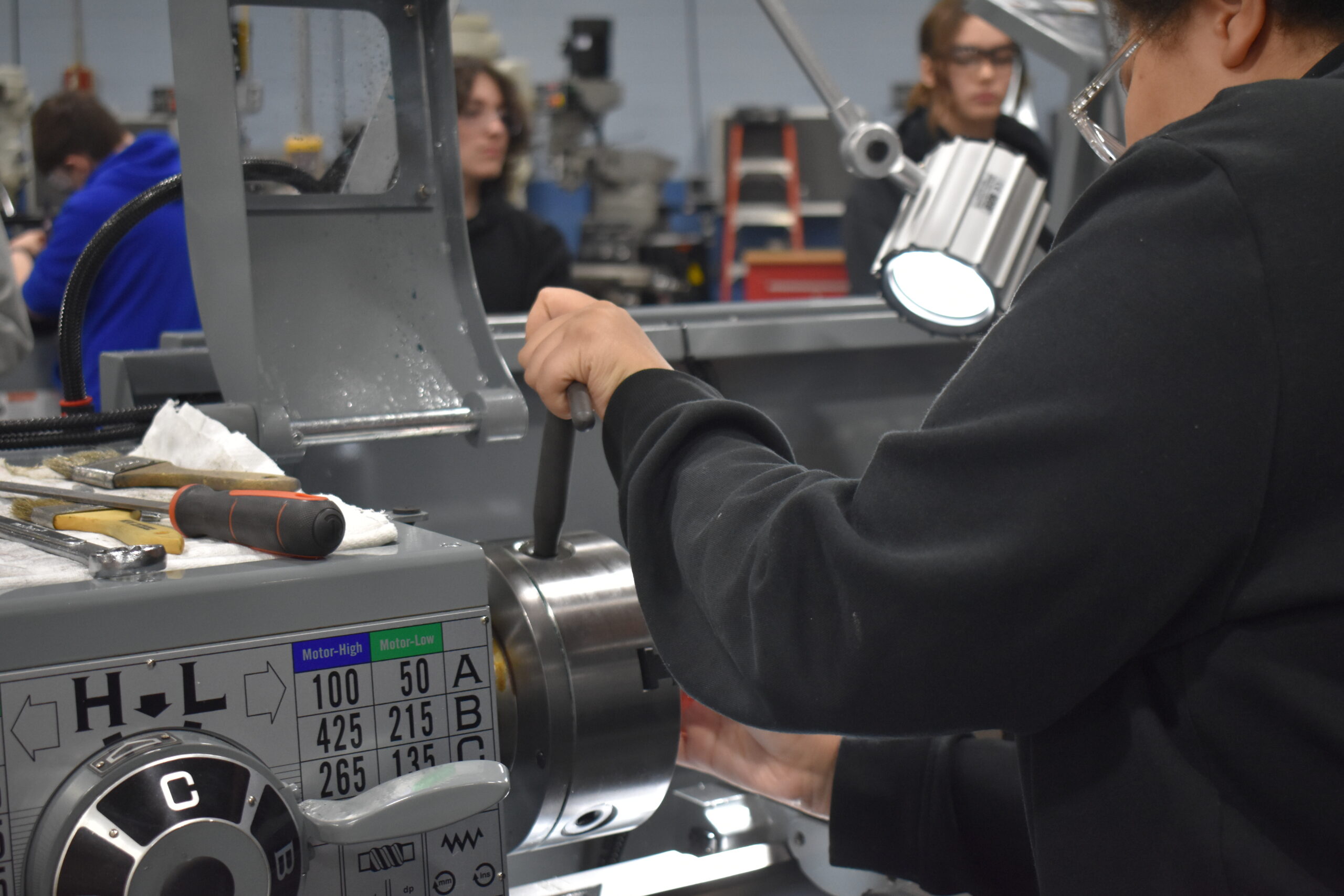

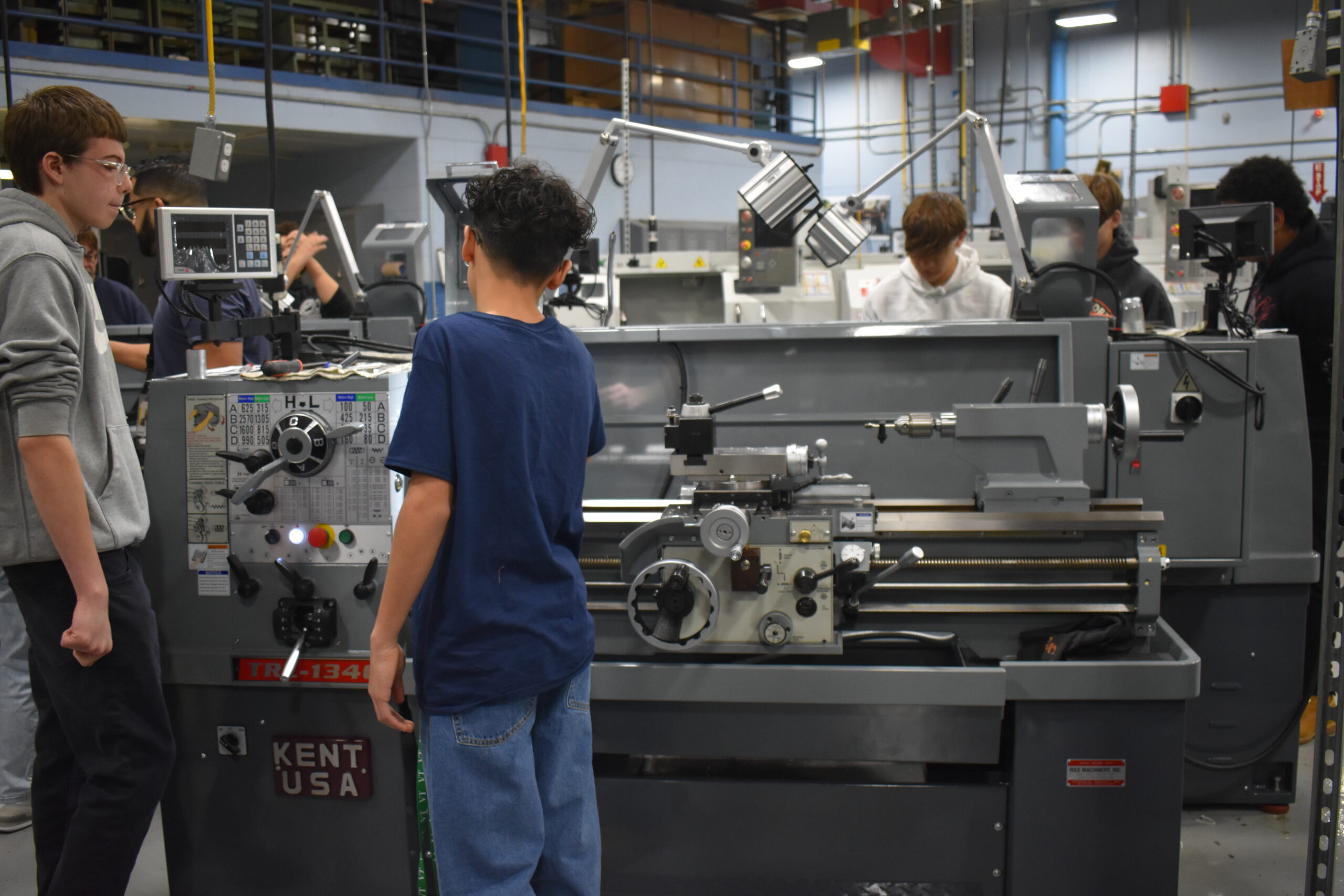

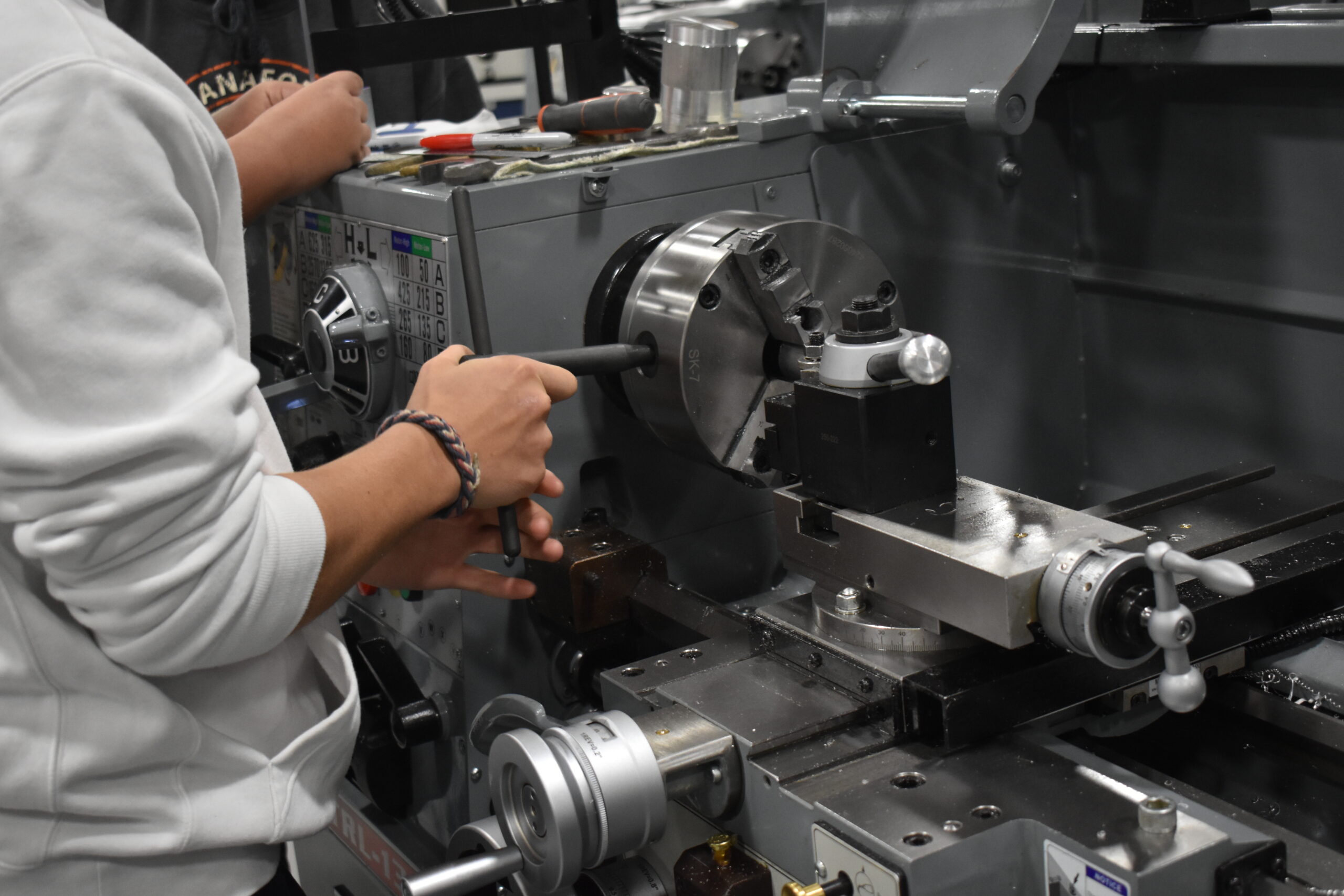

- Manual Machining: Operating Manual Milling Machines and Lathes, Surface Grinders to create precision parts.

- Measurement and Inspection: Using precision measuring instruments, such as Dial Calipers, Micrometers, and Dial Indicators. Digital Height, Gauge Blocks, gage Pins

- Blueprint Reading: Interpreting technical drawings and blueprints.

Computer-Numerical Control (CNC) Machining:

- CNC Programming: Writing CNC programs using CAM software (Mastercam 24).

- CNC Machine Operation: Operating CNC milling machines and lathes to produce complex parts.

- Tooling and Workholding: Selecting and using appropriate tooling and workholding devices.

- Quality Control: Inspecting parts for accuracy and conformance to specifications.

3D Printing:

- 3D Modeling: Creating 3D models using CAD software (SolidWorks).

- 3D Printing: Operating 3D printers to produce physical prototypes and parts.

By the end of the program, students will be well-prepared to enter the workforce or pursue further education in engineering or manufacturing. They will have the skills and knowledge to work in a variety of manufacturing settings, including machine shops, fabrication shops, and manufacturing plants.

Exploratory Program

The Machine Technology Exploratory Program provides an excellent introduction to the world of machining and manufacturing. Through hands-on experiences, students can gain valuable insights into the skills and knowledge required for success in this field.

Key areas of exploration typically include:

- Basic Machine Shop Skills:

- Safety practices and procedures in the machine shop.

- Use of hand tools and measuring instruments (dial calipers, micrometers, etc.).

- Basic machining operations, such as drilling, milling, and turning.

- Manual Machining:

- Operating manual lathes and milling machines to create simple parts.

- Understanding cutting tool geometry and speeds and feeds.

- Computer Numerical Control (CNC) Machining:

- Introduction to CNC programming and operation.

- Using CAM software to create CNC programs.

- Setting up and operating CNC machines.

- 3D Printing:

- Understanding 3D printing technology and its applications.

- Using 3D modeling software to design parts.

- Operating 3D printers to create physical objects.

By the end of the exploratory program, students will have a solid understanding of the fundamentals of machining and manufacturing. They will also be able to make informed decisions about their future career paths, whether it’s pursuing further education in engineering or directly entering the workforce.

Freshman Program

The Grade 9 Machine Technology program lays the groundwork for a successful career in manufacturing. Key areas of focus include:

Safety and Workplace Practices:

- Understanding and adhering to safety regulations and procedures.

- Proper use of personal protective equipment (PPE).

- Workplace organization and cleanliness.

Basic Machine Shop Skills:

- Hand Tools: Using hand tools effectively, such as hammers, wrenches, and files.

- Measuring Instruments: Using precision measuring instruments, including dial calipers, micrometers, and dial indicators.

- Blueprint Reading: Interpreting technical drawings and blueprints.

- Basic Machining: Operating manual machines like lathes and milling machines to create simple parts.

Manufacturing Processes:

- Machining Processes: Understanding cutting processes, such as turning, milling, drilling, and grinding.

- Material Properties: Learning about different materials used in manufacturing, such as metals and plastics.

- Quality Control: Inspecting parts for accuracy and conformance to specifications.

Technical Mathematics:

- Basic Algebra: Applying algebraic principles to solve manufacturing problems.

- Geometry: Using geometric concepts to design and manufacture parts.

- Trigonometry: Understanding trigonometric functions for calculations involving angles and distances.

By the end of the ninth grade, students will have a solid foundation in the fundamentals of machining and manufacturing. They will be well-prepared to advance to more complex projects and specialized skills in their subsequent years of study.

Sophomore Program

The Grade 10 Machine Technology program focuses on expanding students’ skills and knowledge in machining and manufacturing. Key areas of focus include:

Advanced Machining Techniques:

- Manual Machining: Mastering advanced manual machining techniques, including turning, milling, drilling, and surface grinding.

- CNC Machining: Learning advanced CNC programming and operation techniques.

- Tooling and Workholding: Selecting and using appropriate tooling and workholding devices for complex parts.

- Quality Control: Implementing quality control measures to ensure precision and accuracy.

Materials Science:

- Metal Properties: Understanding the properties of different metals, including steel, aluminum, and stainless steel.

- Heat Treatment: Learning about heat treatment processes, such as annealing, hardening, and tempering.

- Material Selection: Selecting appropriate materials for specific applications.

Engineering Design and CAD:

- SolidWorks: Using SolidWorks to create 3D models and 2D drawings.

- Design for Manufacturing: Designing parts and assemblies that are manufacturable.

- Tolerance Analysis: Understanding tolerances and their impact on part quality.

Teamwork and Collaboration:

- Group Projects: Working collaboratively with peers to complete complex projects.

- Communication Skills: Effectively communicating with team members and supervisors.

- Problem-Solving: Identifying and solving problems in a manufacturing environment.

By the end of the tenth grade, students will have a solid understanding of advanced machining techniques, materials science, and engineering design. They will be well-prepared to take on more complex projects in their junior and senior years.

Sophomore Related Class 1

Machining Theory and Blueprint Reading

This introductory course provides a solid foundation in the fundamentals of machining. Key areas of focus include:

Machining Theory:

- Basic Machining Processes: Understanding the principles of turning, milling, drilling, and surface grinding.

- Cutting Tools: Learning about different types of cutting tools and their applications.

- Machine Tool Components: Identifying the components of machine tools, such as spindles, feeds, and controls.

- Workholding Devices: Understanding the use of workholding devices, such as chucks, vises, and fixtures.

Materials Science:

- Metal Properties: Learning about the properties of different metals, such as hardness, ductility, and machinability.

- Material Selection: Choosing the appropriate materials for specific applications.

Safety:

- Shop Safety Rules: Understanding and following safety rules and regulations.

- Personal Protective Equipment (PPE): Using appropriate PPE, such as safety glasses, earplugs, and gloves.

- Emergency Procedures: Knowing how to respond to emergencies in the shop.

Blueprint Reading:

- Interpreting Technical Drawings: Reading and understanding engineering drawings, including orthographic projections and dimensioning.

- Tolerances and Fits: Understanding the concept of tolerances and fits.

By the end of this course, students will have a solid understanding of the fundamentals of machining. They will be able to read blueprints, select appropriate tools and materials, and perform basic machining operations safely and effectively. This foundation will prepare them for more advanced machining courses and hands-on experience in the shop.

Sophomore Related Class 2

Entry Level Math for Machinists

This course provides a solid foundation in mathematics, specifically tailored to the needs of machinists and manufacturing professionals. Key areas of focus include:

Basic Mathematics:

- Arithmetic: Operations with whole numbers, fractions, decimals, and percentages.

- Geometry: Understanding geometric shapes, angles, and trigonometric functions.

- Algebra: Solving algebraic equations and inequalities.

Technical Math:

- Units of Measurement: Converting between different units of measurement (e.g., inches, millimeters).

- Geometric Tolerancing: Understanding and applying geometric tolerances to ensure part accuracy.

- Trigonometry: Using trigonometry to solve problems involving angles, sides, and trigonometric functions.

- Pythagorean Theorem: Applying the Pythagorean theorem to calculate distances and dimensions.

- Shop Trigonometry: Using trigonometry to calculate tapers, angles, and offsets.

Machine Shop Math:

- Calculating Cutting Speeds and Feed Rates: Determining appropriate cutting speeds and feed rates for different materials and machining operations.

- Tool Geometry: Understanding the geometry of cutting tools and their impact on machining performance.

- Tolerance Analysis: Analyzing tolerances to ensure part accuracy and interchangeability.

Problem-Solving and Critical Thinking:

- Applying Math to Real-World Problems: Using mathematical concepts to solve practical problems in the machine shop.

- Data Analysis: Analyzing data from measurements and tests to identify trends and make informed decisions.

By the end of this course, students will be able to:

- Perform basic mathematical calculations accurately and efficiently.

- Apply mathematical concepts to solve real-world machining problems.

- Use measuring tools and instruments to make precise measurements.

- Interpret technical drawings and blueprints.

- Set up and operate machine tools effectively.

This course will provide students with the essential mathematical skills needed to succeed in the field of manufacturing.

Junior Program

The Grade 11 Machine Technology program builds upon the foundational skills acquired in previous years, focusing on advanced machining techniques and engineering design.

Key Areas of Focus:

- Advanced CNC Machining:

- Mastercam programming for complex parts.

- Multi-axis machining.

- G-code optimization.

- Toolpath generation and simulation.

- SolidWorks:

- Advanced 3D modeling techniques.

- Design for Manufacturing and Assembly (DFMA).

- Tolerance analysis and GD&T.

- Engineering Principles:

- Kinematics and dynamics of machine tools.

- Material science and metallurgy.

- Heat treatment and metallurgical processes.

- Electrical and Automation:

- Basic electrical circuits and troubleshooting.

- PLC programming and automation systems.

- Quality Control and Inspection:

- Using precision measuring instruments.

- Statistical process control (SPC).

- Quality assurance techniques.

Hands-on Projects:

- Complex Part Manufacturing: Designing and manufacturing intricate parts, such as gears, cams, and dies.

- Assembly Projects: Assembling mechanical devices and systems.

- Reverse Engineering: Creating 3D models and CNC programs from existing parts.

By the end of the eleventh grade, students will have a strong foundation in advanced machining techniques, engineering design, and quality control. They will be well-prepared to enter the workforce or pursue further education in engineering or manufacturing technology.

Junior Related 1

Technical Math / Intro to MasterCam

This course provides a solid foundation in the mathematical principles and CAM software skills essential for success in manufacturing. Key areas of focus include:

Technical Math:

- Geometry and Trigonometry: Understanding geometric shapes, angles, and trigonometric functions.

- Algebra and Trigonometry: Solving algebraic equations and applying trigonometric principles to calculate dimensions and angles.

- Unit Conversions: Converting between different units of measurement (e.g., inches, millimeters, feet).

- Dimensional Tolerances: Understanding and applying tolerances to ensure part accuracy.

Mastercam Fundamentals:

- User Interface: Navigating the Mastercam interface and understanding its tools and features.

- Part Modeling: Creating 3D models of parts using solid modeling techniques.

- Toolpath Generation: Generating toolpaths for milling, turning, and drilling operations.

- Simulation: Simulating machining processes to visualize toolpaths and identify potential issues.

- Post-Processing: Generating G-code for CNC machines.

Integration of Math and CAM:

- Calculating Cutting Speeds and Feed Rates: Using mathematical formulas to determine optimal cutting parameters.

- Toolpath Optimization: Optimizing toolpaths to minimize machining time and improve part quality.

- Tolerance Analysis: Analyzing tolerances to ensure part accuracy.

By the end of this course, students will be able to:

- Apply mathematical concepts to solve machining problems.

- Use Mastercam to create 3D models and generate CNC programs.

- Simulate and optimize machining processes.

- Understand the relationship between math and machining.

This course provides a strong foundation for students to advance to more complex machining projects and develop expertise in CNC programming and operation.

Junior Related 2

Applied Advanced Manufacturing Fundamental

This advanced course builds upon the foundational knowledge and skills acquired in previous machining courses. Key areas of focus include:

Advanced Machining Processes:

- High-Speed Machining (HSM): Understanding the principles of HSM and its benefits.

- Five-Axis Machining: Programming and operating five-axis CNC machines.

- EDM (Electrical Discharge Machining): Understanding the principles of EDM and its applications.

- Laser Cutting: Understanding the principles of laser cutting and its applications.

Advanced Materials and Tooling:

- Tool Material Selection: Choosing the appropriate cutting tool materials for different applications.

- Tool Geometry: Understanding the geometry of cutting tools and their impact on machining performance.

- Coolant Selection and Application: Selecting the appropriate coolant for different machining operations.

- Workholding: Designing and using advanced workholding techniques.

Quality Control and Inspection:

- Statistical Process Control (SPC): Using SPC techniques to monitor and control process variability.

- Metrology: Using precision measuring instruments to verify part dimensions and tolerances.

- Root Cause Analysis: Identifying and addressing the root causes of quality issues.

Computer-Aided Manufacturing (CAM):

- Advanced CAM Programming: Creating complex CNC programs using advanced CAM software.

- Simulation and Optimization: Simulating machining processes to optimize toolpaths and cycle times.

- Post-Processing: Generating machine-specific code from CAM programs.

Industry Standards and Best Practices:

- Industry Standards: Understanding and adhering to industry standards, such as ISO and ASME.

- Lean Manufacturing: Implementing lean manufacturing principles to improve efficiency and reduce waste.

- Safety Practices: Adhering to safety protocols and using personal protective equipment.

By the end of this course, students will have a deep understanding of advanced machining techniques and be able to apply these skills to complex manufacturing projects. They will be well-prepared to enter the workforce as skilled machinists or pursue further education in engineering or manufacturing technology.

Senior Program

The Grade 12 Machine Technology program culminates in a comprehensive curriculum that prepares students for advanced manufacturing careers. Key areas of focus include:

Advanced CNC Machining:

- Complex Part Machining: Programming and machining complex parts requiring multiple setups and tool changes.

- High-Speed Machining: Optimizing machining parameters for high-speed, high-precision machining.

- 5-Axis Machining: Programming and operating 5-axis CNC machines.

- Mold and Die Making: Designing and manufacturing molds and dies using advanced machining techniques.

CAD/CAM Integration:

- Advanced SolidWorks: Creating complex 3D models and assemblies.

- Mastercam Programming: Generating efficient and optimized CNC programs.

- Simulation and Optimization: Using simulation tools to predict machining performance and optimize toolpaths.

Quality Assurance and Inspection:

- Metrology: Using precision measuring instruments to verify part dimensions and tolerances.

- Statistical Process Control (SPC): Implementing SPC techniques to monitor and control manufacturing processes.

- Root Cause Analysis: Identifying and addressing the root causes of quality issues.

Industry Standards and Best Practices:

- ASME Y14.5: Understanding and applying GD&T principles.

- Industry Standards: Adhering to industry standards and best practices.

- Lean Manufacturing: Implementing lean manufacturing principles to improve efficiency and reduce waste.

Senior Projects:

- Individual Projects: Undertaking individual projects to demonstrate mastery of advanced machining skills.

- Team Projects: Collaborating with peers to complete complex projects.

- SkillsUSA Competition: Preparing for and participating in SkillsUSA competitions.

By the end of the senior year, students will be well-prepared to enter the workforce or pursue further education in engineering or manufacturing technology. They will have the skills and knowledge to work in a variety of manufacturing settings, including aerospace, automotive, and medical device manufacturing.

Senior Related 1

Advanced MasterCam

This advanced Mastercam course is designed to build upon students’ foundational knowledge and skills in computer-aided manufacturing. Key areas of focus include:

Advanced Mastercam Techniques:

- Complex Part Programming: Creating CNC programs for intricate parts with multiple setups and tool changes.

- Multi-Axis Machining: Programming and simulating multi-axis machining operations (3-axis, 4-axis, and 5-axis).

- High-Speed Machining (HSM): Optimizing toolpaths for high-speed, high-precision machining.

- Toolpath Verification and Simulation: Using simulation tools to verify toolpaths and identify potential collisions.

- Post-Processing: Generating machine-specific G-code for different CNC machines.

Advanced CAM Strategies:

- Workholding and Fixturing: Designing and implementing effective workholding strategies.

- Tool Selection and Optimization: Selecting appropriate cutting tools and optimizing cutting parameters.

- Machining Strategies: Developing efficient machining strategies, such as roughing and finishing operations.

- Tolerance Analysis: Analyzing tolerances and ensuring part accuracy.

Industry Standards and Best Practices:

- GD&T (Geometric Dimensioning and Tolerancing): Applying GD&T principles to create accurate and precise parts.

- Industry Standards: Adhering to industry standards and best practices.

- Quality Control: Implementing quality control measures to ensure part quality.

By the end of this course, students will be proficient in using Mastercam to create complex CNC programs, optimize machining processes, and produce high-quality parts. They will be well-prepared for advanced manufacturing roles and be able to contribute to the success of manufacturing organizations.

Senior Related 2

Applied Trigonometry – Elective

This course provides a comprehensive understanding of trigonometry and its practical applications in the machining industry. Key areas of focus include:

Trigonometric Functions:

- Basic Trigonometric Functions: Understanding sine, cosine, and tangent functions.

- Right Triangle Trigonometry: Solving right triangles using trigonometric ratios.

- Trigonometric Identities: Applying trigonometric identities to simplify expressions and solve equations.

- Inverse Trigonometric Functions: Using inverse trigonometric functions to find angles.

Applications in Machining:

- Calculating Angles and Distances: Using trigonometry to calculate angles, distances, and offsets.

- Tool Geometry: Analyzing the geometry of cutting tools, including rake angles, clearance angles, and point angles.

- Workholding: Designing and setting up workholding fixtures.

- Coordinate Systems: Understanding Cartesian and polar coordinate systems.

- CNC Programming: Using trigonometric functions to calculate toolpath coordinates.

Problem-Solving and Critical Thinking:

- Real-world Applications: Applying trigonometry to solve practical machining problems.

- Problem-Solving Strategies: Developing problem-solving strategies to tackle complex challenges.

- Critical Thinking: Analyzing problems, identifying solutions, and making informed decisions.

By the end of this course, students will be able to:

- Apply trigonometric functions to solve machining problems.

- Use trigonometry to calculate cutting tool angles and offsets.

- Design and create complex parts using trigonometry.

- Troubleshoot machining issues using trigonometry.

- Communicate technical information effectively using mathematical language.

This course will provide students with the essential mathematical skills to excel in the field of machining and manufacturing.

Certifications

- Career Safe Certification, recognized by the Occupational Safety and Health Administration (OSHA)

- Certified SolidWorks Associate

- Manufacturing Advancement Center Workforce Innovation Collaborative (MACWIC)

- MACWIC Level 1

- MACWIC Level 2

- NIMS

Career Opportunities

- Machinist

- Quality Control & Inspection

- CNC Operator

- Mold Maker

- CNC Programmer

- CNC Set-up Technician

- Machine Repair Technician

- Research and Development

- Jig & Fixture Maker

- Tool and Die Maker

- Entrepreneur/Inventor

Post-Secondary Education

Two Year College Opportunities:

Manufacturing Technology

Electromechanical Technology

Industrial Engineering Technology

Mechanical Engineering Technology

Industrial Design

Four Year College Opportunities:

Mechanical Engineer

Electromechanical Engineer

Industrial Engineer

Metallurgy Robotics Engineer

Apprenticeship: State Certificate:

Manufacturing Advancement Center Workforce Innovation Collaboration statewide apprentice agreement.